Stainless Valve Co., Inc.

Stargate O-Port Valve

What Is A SVC Stargate-O-Port Valve? What Are The Advantages?

The main characteristic of this type of valve, also called slide-gate valve or through-port valve is the well-guided blade passing through both ends of the valve body, having a hole in the middle of the blade. This basic concept has a series of advantages:

- The valves are the choice for handling solids in flow media. Liquid, gas and solid flow media are accepted.

- Proper actuation of the valve is guaranteed.

- No material gets trapped in the bottom of the valve.

- The valve has a class VI shut-off, independent of the pressure differential between upstream and downstream side. The tightness of the shut off does not depend on a pressure differential between the upstream and downstream side.

- The valve does not need lubrication.

- The valve does not require maintenance.

- The valve can be used as shut-off valve, flow control valve and line blind.

- Even in a partially open position the valve has a straight flow direction, different from ball valves where the flow is re-directed twice.

- Short face to face dimension, a fraction of the space requirement of a ball valve in the flow direction.

- Foreign matter does not get jammed between the gate and the body. This prevents seat damage so that the valve always seats and seals well.

- Long leak free operation, through the valve and from the valve body.

- Pressure shock waves, aggressive flow media are well handled by these valves.

- The valves can be installed in any position in the pipe; they do not have a preferential flow direction.

- Over 97% of the body thickness is solid material, resulting in a very stiff valve body. 3% 0r less are the gaps between the blade and the side plates.

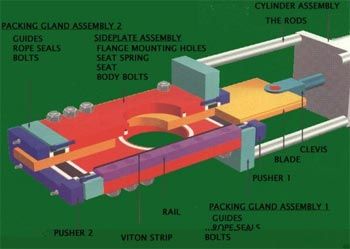

Characteristics Of The SVC Stargate-O-Port Design

- Very rugged design manufactured to tight tolerances for many years of trouble free service.

- No metal-to-metal contact. Blade moves in PTFE guides. The PTFE seats in the valve are protected and away from the flow area. They are rubber spring-loaded for tight shut-off, independent of the pressure differential between upstream and downstream side (up to 450 deg F).

- The blade is sealed by a rope/chevron/u-seal combination. There is a minimum gap between the gate and the body, which prevents foreign matter from getting jammed between the gate and the body.

- Foreign matter cannot get forced between the blade and seat. This prevents seat damage so that the valve always seats and seals well.

- Spring-loaded followers ensure automatic re-compression of packing for long leak free operation.

- Locking mechanism locks blade in open and/or closed position for greater safety.

- The valves are made in stainless steel 304, 316, 317, Hastelloy, titanium, carbon steel, and other materials available in plate form.

- The valves are usually actuated by type A pneumatic actuators. Actuation forces are 4000, 6000, 9000, or 12000 lbs for 8”, 10” 12” 0r 14” actuators respectively. Hydraulic, electric, gear, or straight manual actuators are optional.

- The opening and closing speed can be varied with the airflow between typically 10 and 60 seconds.

- The valves are mostly laid out for 150, 300 or 600# service, higher pressure ratings are available.

- The 150 psi valves have take-out dimensions as specified in the MSS standard.

- The flanges of the piping are directly bolted onto the side plates of the valves with a total of four bolts reaching through the valve body and through both flanges for improved strength of the assembly.

- For higher temperature applications graphite based seats, blade guides and packing materials are used.

- Full port (discharge area equal to pipe area) is standard even at takeout dimensions of reduced port ball valves or shorter. No flow restrictions exist due to smooth unobstructed discharge area. This assures maximum production capacity.

- The clearance between the body and the blade is very small. Bolted body parts maintain these clearances, yet provide ease of repair should it be required after many years of service.

- Different configurations of the valve layout for applications with space constraints are available. Variations of the basic principle allow manufacture of for example diverter valves with one or two inlets and outlets, purge valves, etc.

Click here for more Product Details from

Stainless Valve Co., Inc....