Contact Details:

igus

PO Box 14349

East Providence

Rhode Island

02914

United States of America

Tel: +1 401 4382200

Fax: +1 401 4387270

Send Enquiry | Company Information

Smart plastics for Industry 4.0

Product News Wednesday, May 11, 2016: igus

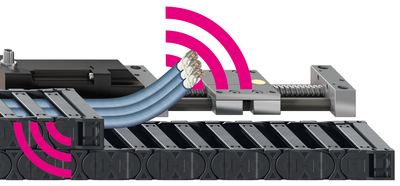

Intelligent cables, cable management, and linear solutions from igus increase plant automation

High performance plastics for motion, or “motion plastics,” defy rain, salt, extreme temperatures, oils and chemicals, while maintaining light weight, dynamic motion, energy efficiency, and low costs. At the 2016 Hannover Messe, igus introduced an innovative range of “smart plastics” for Industry 4.0 with the goal of making preventative maintenance easier, reducing costs in the factories of the future.

Today, high performance plastics are used in moving applications of all types, including medical and lab equipment, bicycles, packaging lines, robotics, machine tools, and crane facilities. Thanks to decades of testing results, igus is able to make accurate predictions regarding the expected service life of their products in particular applications. Now, intelligent plastic solutions can ensure additional reliability in factories and applications.

Smart plastics for preventative maintenance

Networked smart plastics, which incorporate a range of sensors and monitoring modules, can expand the possibilities of preventative maintenance and increase uptime and reduce unexpected repairs and maintenance. Intelligent Energy Chain cable management systems DryLin linear solutions, and Chainflex continuous-flex cables constantly monitor themselves, and provide an early failure warnings to plant supervisors. This new range of products, called “isense” also has the ability to network with the igus communication module, or ICOM, a direct integration with the factory/application interface.

Automated maintenance saves time and money

isense systems are capable of monitoring the service life of the Energy Chain, cable, or linear system. Through continuous distance measurements and calculations of the system’s parameters, as well as test data, it is possible to also reliably predict the functionality of the operation in real-time. If measured values exceed the set parameters, the intelligent isense products indicate the remaining product lifetime, enabling timely maintenance and/or replacement. When networked with the ICOM system, options such as the direct ordering of spare parts and maintenance commissioning can be scheduled, lowering maintenance time and costs even further.

For more information about how smart plastics can enable preventative maintenance, please visit www.igus.eu/smartplastics.