Contact Details:

Telesis Technologies, Inc.

28181 River Drive

Circleville

OH

43113

United States of America

Tel: +1 740 477-5000

Fax: +1 740 477-5001

Send Enquiry | Company Information

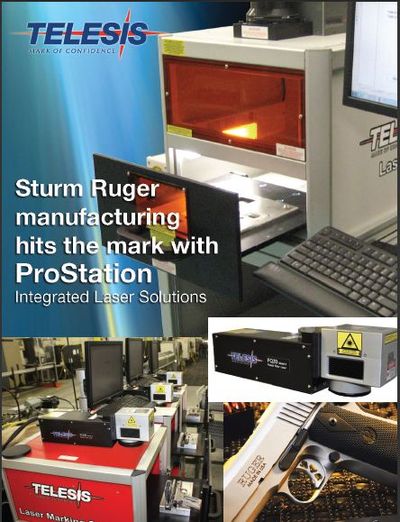

Sturm Ruger manufacturing hits the mark with Telesis ProStation integrated laser marking systems

Company News Wednesday, January 30, 2013: Telesis Technologies, Inc.

COMPANY CONTACT

John Heinrich

Marketing

Voice: 740-420-6527

Fax: 740-477-5001

John.Heinrich@telesistech.com

FOR IMMEDIATE RELEASE

Sturm Ruger manufacturing hits the mark with

Telesis ProStation integrated laser marking systems

Sturm, Ruger & Co., Inc. (Southport, CT) is one of the nation’s leading manufacturers of high-quality firearms for the commercial sporting market, and the only full-line manufacturer of American-made firearms, including the awardwinning SR1911 pistol. This gun, along with all other Sturm, Ruger & Co semiautomatic handguns, is manufactured at the company’s almost 250,000 ft2 Prescott, AZ, manufacturing plant. To meet regulations of the U.S. government’s Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF), the company has to mark several components in each handgun with information about the gun model, caliber, manufacturer, serial number and other details. Initially, these marks were all done by roll marking, which involved “rolling” a cylindrical die made of metal across a secondary surface made of a softer metal to create a mark, serial number, or logo.

“Like automobiles and aircraft, firearm designs have become lighter, using harder metals and thinner-walled designs,” explains Michael Scoggins, chief manufacturing engineer at Sturm, Ruger & Co. “Historically, we roll-marked everything, but as our parts became harder – we started specifying the hardness of our firearms components into the mid-40s of the Rockwell C Scale and beyond – we had to push harder on the parts to make a mark. This was problematic for the components and fixtures as well as the roll die. We had to go to exotic die materials to get 250 impressions from a single die, and sometimes, we only got two impressions for a $275 die on top of having a well-paid specialist at the machines to correctly install the die on the roller, which is sort of an art.”

With regards to marking serial numbers with mechanical roll marking heads, “For numbers like 1s and 7s that had room on each side to push the material, the dies worked pretty well,” he continues. “But we were breaking 0s on a regular basis because there’s nowhere to push the material in the center, and additionally we’d have to polish down the splash-up material from the roll mark. On top of that, the roll markers that hold the die are about $900 per digit. The parts and labor, changeovers, and downtime were costing us a lot. When we began to explore a laser marking solution, we realized we could eliminate tooling replacement costs, and reduce our changeovers to 15 to 30 seconds – mainly the time required to key up a new program.”

The ATF specifies that the markings be at least 1/16thof an inch high with a minimum of 0.003-inch penetration. To avoid any regulatory issues, Sturm, Ruger & Co. pushes it to 0.008-inch penetration. After considerable research, Scoggins selected a ytterbium-doped pulsed fiber laser marking system from Telesis Technologies Inc. (Circleville, OH).

“When we first started working with Telesis, their fiber laser marking system had only been on the market for a year, but what most attracted me to Telesis was their willingness to listen to my requirements and to work together as a team to develop a solution without a bunch of sales pressure,” adds Scoggins. “The lasers we use today – and we have about 20 here at this facility and are adding more to our Newport, NH, facility – are not standard products. This was really a cooperative venture between Telesis and Ruger.”

Scoggins needed a laser marking system that could work around the clock with high uptime and minimal maintenance. “We’re not making key rings here,” explains Scoggins. “We needed something that was going to run 24/7 in a working, industrial shop environment.”

The first laser paid for itself in less than a year. “We saved tens of thousands of dollars a year by moving from roll marking to laser marking and thousands more in labor savings because we don’t need a specialist to replace aging and broken dies.”

After the success of the first laser systems, Scoggins returned to Telesis Technologies, saying he needed a smaller system to fit on the shop floor – preferably a mobile laser marking system with a drawer fixture for small gun parts coupled with higher laser power. This request eventually led to Telesis Technologies’ ProStation integrated laser marking system, which is housed in a mobile enclosure and offered with a higher power (30W) laser for higher throughput at the laser marking stations.

“We developed a number of fixtures that held different parts exactly in focus for the laser, which accelerated our loading and change over times because we didn’t need to adjust the marking system at all,” notes Scoggins. “Just load, click, and you’re done.”

Based on Scoggins’ and other customer feedback, Telesis recently added a small machine vision camera-based system that visually checks to make sure a serial number or other mark isn’t already present. If not, the ProStation system contacts the company’s product inventory database and retrieves the next serial number for marking.

At one time, Scoggins explored a less expensive laser marking system, but the results were disastrous from day one. “I went back to Telesis and said we would like to do some value orders, but we need to get the cost down. We worked together and came up with a solution. The extra cost was worth it because having them on our side was priceless.”

Actually, Scoggins has been able to put a price on the change to laser marking over roll marking. In addition to the thousands in dollars in annual maintenance and labor savings, the Prescott facility now sells custom marking for special product line runs and for offerings like the National Rifle Association’s commemorative guns.

“We paint red and white dots for safety indicators, one gun was giving us a problem getting paint to stick to it, so we used the laser to roughen the surface, and that fixed the problem. We’ve used the lasers in R&D also, when designing new ammunition magazine geometries and latch locations, burning through 0.03 in. of Rockwell 55 material. We’ve even explored welding with the laser, although that’s in the early stages,” says Scoggins.

“In addition to die and labor savings, we’ve saved time setting up new production lines,” he adds. “Today, we’re able to use our CAD designs and port the data to the laser system to program the marking procedure thanks to some help from the Telesis guys.” Out of several products, Sturm, Ruger & Co’s Prescott facility only uses roll marking on one legacy line of guns, the Mark III 22 pistol.

“Ruger recognized one of Telesis’ core values being customer intimacy,” notes Merrill Apter, vice president, sales, at Telesis Technologies, Inc. “Another is our mission- specific focus on marking and engraving solutions. Telesis is unique in that it not only offers mechanical Pinstamp® and TeleScribe® scribe systems but gas, solid-state, and fiber-laser solutions for a variety of high-use applications that demand high uptime, low maintenance, and ease of use. From 355nm to 10.6μm lasers, all Telesis equipment is manufactured in the USA and supported globally through sales, service, and application offices in China, UK, Germany, Russia and the NL.

Telesis Technologies

28181 River Drive, Circleville, OH, 43113.

1-800-654-5696

www.telesis.com

Reprinted with revisions to format, from the November/December 2012 edition of INDUSTRIAL LASER SOLUTIONS

Copyright 2012 by PennWell Corporation