Contact Details:

EngNet - Engineering Network

11121 Carmel Commons Blvd.

Charlotte

NC

28226

United States of America

Tel: +01 704 5413311

Fax: +01 704 9430560

Send Enquiry | Company Information

3D Printing Brings the Science Lab to Your Backyard

Product News Tuesday, September 25, 2012: EngNet - Engineering Network

High-end scientific tools can go into the tens or hundreds of thousands of dollars. But thanks to 3D printing and a plethora of free, modifiable online plans, both professionals and DIYers are building their own equipment for a fraction of the cost, opening up a new world for backyard Einsteins and university researchers alike.

3D printers have already become a go-to tool for ambitious do-it-yourselfers. Now they’re breaking down barriers for DIY scientists, who are part of an online community designing, sharing, and improving the high powered-machines once only found in research labs.

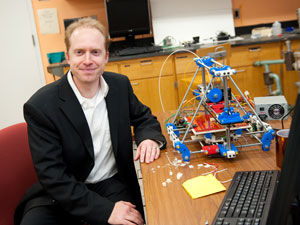

"No lie, this has saved me thousands of dollars," says Joshua Pearce, an associate professor of materials science and engineering at Michigan Technological University. In an essay in the journal Science this week, Pearce, who researches photovoltaics (solar energy), praises the revolution in low-cost science made possible by crafting your own lab instruments at a steep discount. One popular printer, the RepRap, costs less than $1000 and can reprint more and more RepRaps. It is controlled by a small Arduino computer, an open source project in electric circuitry, which costs $30 dollars.

Pearce points to the more than 30,000 objects available at Thingiverse.com, a free and open source hardware database that began with basic toy designs and now includes lab equipment. There’s the Dremelfuge an "ultracentrifuge that spins test tubes at up to 33,000 rpm with 50,000 times the force of Earth’s gravity. Scientists use such a device to separate blood cells or bacterial cells into their component parts in seconds. But a Beckman Coulter Avanti J series rotor capable of 30,000 rpm costs more than $10,000 from the manufacturer.

Given that a centrifuge is just one of the tools you’d need to perform even a basic lab experiment, costs can get prohibitive pretty quickly—unless you can access plans online and print them on your 3D printer. "An ultracentrifuge was hundreds of thousands of dollars, and now you can make one in a bucket in your backyard," Pearce says. "You can use it to spin down DNA or to spin your soup."

In August, software engineer Haydn Vestal uploaded a 1 kilowatt wind turbine that uses a 3D-printable generator and only requires magnets and wire to complete. "It’s not enough to power the average American home, but enough to power the conscientious American’s home," Pearce says. The design was so popular that Vestal pitched the idea as a startup. "My pitch was doing hardware for the cost of software," Vestal says. He estimates the printable turbine costs only about 30 percent as much as buying an ordinary one. "[Thingiverse] lowers a lot of the development cost if you’re making something that’s an amalgamation of other printable parts you can find."

Once one design is up, it can immediately be modified or built upon to make more complicated devices. For example, Pearce and his colleagues are developing a solar-powered water pasteurization system. The device calls for heat exchangers that can be made of plastic, but only if it is cut to almost impossible thinness. So Pearce’s team found a 3D printable laser cutter, which they modified into a device for welding plastic garbage bags together. Presto: heat exchangers. "It used to be thousands of dollars for a prototype, but now you can make one an hour, one every half hour if you want."

Pearce says sites like Thingiverse—where a new object is added every 5 minutes—are now a source of affordable lab equipment options for high schools and the developing world. "Many are a factor of 100 lower cost than market price," he says. But 3D printing can help high-powered research labs, too, through the use of rapid prototyping.

A top-of-the-line 3D printer could cost tens or hundreds of thousands of dollars, but once a lab has one, the cost of creating new prototypes drops dramatically compared to building them in other ways, or paying outside agencies to print them.

Michael Gehm, who directs the Laboratory for Engineering Non-traditional Sensors (LENS) at the University of Arizona, tells PM he purchased a $100,000 rapid prototyper for his graduate students to make mechanical sensors. It also inspired him to try applying it to electrical circuitry and optics. A few tweaks later, Gehm had made the first hologram in terahertz wavelength light. (It looks like a plastic slab, because terahertz light isn’t visible to the human eye.)

Source: http://www.popularmechanics.com/technology/gadgets/tools/3d-printing-brings-the-science-lab-to-your-backyard-12669407