Contact Details:

In2Connect Europe Ltd

Acton Street

Long Eaton

Nottingham

NG10 1FT

United Kingdom

Tel: +44 (0)115 901 1209

Fax: +44 (0)115 901 1117

Send Enquiry | Company Information

Flexible Printed Circuits

Product News Tuesday, April 11, 2006: In2Connect Europe Ltd

UK design engineers have new local contact point for "Advanced Flexible Circuits Inc. of the USA" ~ the Rigid-Flex and Flexible circuit specialists.

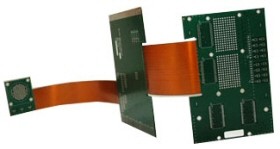

Flexible printed circuits were designed as a space and weight saving replacement for traditional cabling and connectors in point-to-point interconnections. There are primarily 4 types of flexible circuit ~ Single-sided, Double sided, Multilayer and Rigid-Flex. The lack of mechanical connectors and elimination of manual wiring in an integrated circuit reduce wiring errors and greatly increase signal quality and impedance, whilst the circuit fits into spaces that no standard cable and connector harness would.

The circuit laminate for plated-through-hole and multilayer boards is generally constructed from woven glass reinforced epoxy resin with electrodeposited copper foil tracks in thicknesses of 18 microns (half-ounce) and track spacing from 0.005” to 0.002”. Flame Retardant ‘FR4’ (IPC 4101/21) or High Temperature FR4 (IPC 4101/24/26/28) laminates are the mainstay of the printed circuit industry.

Single sided are normally specified for dynamic flexing applications such as printers, disk drives. and internal laptop to screen wiring. Such AFC products have reliably undergone 500 million flex cycles without failure.

Double sided and multilayer are used in relatively static applications where increased circuit density is required.

Rigid-flex types combine elements of flexible circuitry with rigid boards, almost entirely negating the use of mechanical connectors, and are great for motor vehicle dashboard cluster wiring, hand-held communication devices, etc. ~ especially those requiring strain free bonding of SMT devices. These hybrid hard board/flex circuits can have up to 20 layers of flex interconnects, sandwiched between rigid outer layers.

Vibrations and shocks that would crack rigid PCBs have little or no effect on flexi circuits. The base material on which the signal circuits are plated will dictate the temperature range for a given integrated circuit. To ensure higher yields and customer satisfaction, AFC design engineers, quality, and manufacturing teams work with the client to assess the thermal, mechanical and environmental situation so as to offer the optimum materials, construction, solderability and cost for a given task. The AFC "prototype-to-production" program lowers overall production costs, eliminates the need for multiple suppliers, and saves time in creating circuits for Military aircraft, Missiles, Cockpit radios, Radar guidance and flight control systems, Ground support instrumentation, Satellite systems, and Navigational instruments; as well as medical and industrial process control.