Contact Details:

OC Robotics

Unit 5

Abbey Wood Business Park

Filton

Bristol

Bristol

BS34 7JU

United Kingdom

Tel: +44 (0)117 3144700

Fax: +44 (0)117 3144799

Send Enquiry | Company Information

Nuclear snake-arm robots

Product News Wednesday, June 23, 2010: OC Robotics

In May 2010 OC Robotics and OPG IM&CS completed the first deployment of a new snake-arm robot designed to conduct inspections within the Upper Feeder Cabinets of CANDU reactors.

Upper Feeder Cabinet (UFC)

The UFC contains primary coolant pipe work and is located a few meters above the reactor face. During operation pressurised D20 enters the reactor fuel channels at 250ºC and exits at 290ºC. The UFC cools to 40ºC during an outage. Radiation hazards include hot spots, contamination and Tritium (hence air suits). Dose rates are100 to 400 mRem/hour. The UFC is also a confined space with some crawl-only access and limited space to turn around.

Objectives

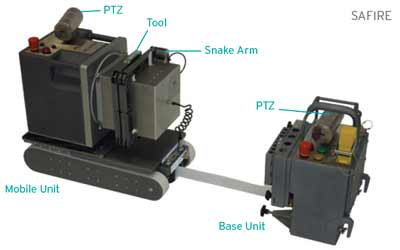

SAFIRE is designed to reduce operator dose and increase the amount and quality of captured data. SAFIRE is a stable, controllable platform from which to acquire video and still images. It is designed to reach 1oo% of the UFC. Real time remote control enables feedback, thought and learning. Sub-optimal air suits are replaced with ‘calm control’.

Snake-arm

The 2.2m long 25mm wide snake-arm is mounted on a mobile vehicle which is driven remotely along walkways in the UFC. The snake-arm is stowed coiled for compactness and is deployed by unwinding and nose-following between the pipes. The snake-arm can be deployed at any angle to reach below or above the walkway. Tool mounted cameras are used for navigation and image capture. PTZ cameras on the mobile and base units provide scene views and additional inspection capability.

Operation

Set-up was completed in 70 minutes from first entry into the vault to remote operation. Tear-down took 30 minutes. SAFIRE completed the pre-defined inspection scope in one 12 hour shift. 24/7 multi-day deployments using teams of operators are planned for future outages.

Training

OC Robotics simulation and training software and full scale mockups were used extensively during testing and for pre-outage rehearsals.

Conclusions

The first deployment at OPG’s Pickering plant achieved all the target objectives including set-up and tear down times, operator dose reduction and the full inspection scope. SAFIRE enables improved data collection and reduces operator dose. Deployment of additional NDT tools is planned.