Contact Details:

Control Lubrication Systems cc

20 Aalwyn Street

Randpark Ridge

Randburg

Gauteng

2194

South Africa

Tel: +27 (0)11 793 6101

Fax: +27 (0)11 793 6292

Send Enquiry | Company Information

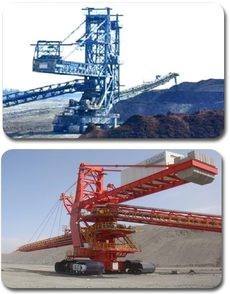

Spreader Lubrication

Product News Wednesday, February 24, 2016: Control Lubrication Systems cc

Spreaders are used in the open pit mining industry to move or “spread “different sorts of raw materials from one location to another.

Spreaders can be found in Mines, where different environmental conditions are to be taken into consideration.

Some of these conditions such as humidity, temperature, dust contamination, rust considerations will affect the design of the machine and the components used.

A spreader is fully mobile and has many moving parts. These parts include for example chains, tracks, wheels, pulleys, drive belts, slew decks and booms.

Most of these moving parts are able to move via bearings. In order for the bearings to move smoothly and accurately lubricants are used to stop the metal surfaces from wearing out. When there are many lubrication points an automatic lubrication system can be used to renew the lubricant in regular intervals and increase the life expectancy of the bearings.

Dropsa Lubrications systems provided Sandvik Materials Handling a specialized solution to allow the machines to be lubricated even at cold temperature and ensure no damage to the bearings.

Benefits achieved

THE SPECIALIST DROPSA ENGINEERS SIMULATED THE LOW TEMPERATURE CONDITIONS USING THEIR REFRIGERATION TESTING FACILITIES AND HELPED TO DESIGN THE SYSTEM USING THE DATA MEASURED DURING THE TESTS.

Dropsa developed specialist grease to work with the system and which meant no additional heating for the pipes was necessary and it was not necessary to increase the dimensions of the pipes. The Sandvik engineers were very satisfied with the fast service and expert advice provided from Dropsa for the lubrication system.

DROPSA PRODUCTS AND SERVICE PROVIDE

THE NECESSARY PERFORMANCE

REQUIRED FOR THE ADVANCED

TECHNOLOGY OF SANDVIK MACHINERY.