Contact Details:

OC Robotics

Unit 5

Abbey Wood Business Park

Filton

Bristol

Bristol

BS34 7JU

United Kingdom

Tel: +44 (0)117 3144700

Fax: +44 (0)117 3144799

Send Enquiry | Company Information

Nuclear decommissioning case study: LaserSnake

Company News Wednesday, March 14, 2012: OC Robotics

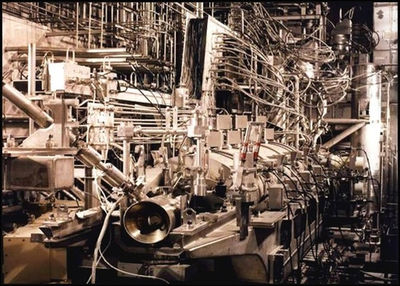

In 2011 OC Robotics led a collaborative project with TWI Ltd as part of a UK Technology Strategy Board competition for nuclear R&D feasibility studies. For this study a snake-arm robot was combined with a 5kW laser to enable a selective, remote-controlled approach to dismantling and decommissioning complex structures in hazardous and confined nuclear environments.

Objectives

Decommissioning of nuclear facilities represents a critical long-term challenge to the industry. This project aimed to demonstrate a system that could perform remote single-sided cutting using a fibre laser, which could ultimately be used in a real-world nuclear environment to dismantle vessels, support structures, flasks and pipe work.

Key to achieving this was to show that the snake-arm was capable of repeatedly following the precise tool paths that are required for laser cutting and other processes. The flexibility of the LaserSnake system also allows it to cut access holes in confined spaces through which it can enter.

Design

TWI Ltd investigated the laser’s cutting capabilities on materials and thicknesses representing pressure vessels, I-beams, box structures and tubes. As well as developing the laser’s optics, they devised cutting techniques that are pertinent to nuclear applications.

A 2.5m long, 100mm diameter self-supporting snake-arm robot with integrated navigation camera and lighting was adapted to carry the laser cutting head. The snake-arm control system co-ordinated tip motion with the laser control to cut a variety of different substrates.

Operation

LaserSnake was operated in a mock-up through a 1m long, 200mm diameter penetration that simulates a cell wall. Inside the mock-up was a representative vessel and pipe work. The snake-arm cut a hole in the vessel wall to allow it access beyond. From here the snake-arm avoided obstacle and pre-programmed cutting paths were used to cut the target pipes.

Results

TWI Ltd demonstrated that the laser cutting head was able to cut thick walled pipes, 25mm thick 304 stainless steel plate, 50mm thick C-Mn steel plate, and concrete up to 87mm thick. The LaserSnake project demonstrated single-side laser cutting for remote disassembly in confined spaces. Snake-arm solutions can deliver cost reductions and efficiency improvements for nuclear decommissioning whilst improving safety by minimising the level of human intervention.

Demonstrations for you?

If you're thinking of using a snake-arm robot for your project, contact us to find out more about setting up relevant demonstrations.