Contact Details:

System Devices UK Ltd

1 Beeston Court

Runcorn

Cheshire

WA7 1SS

United Kingdom

Tel: +44 (0)1928 571977

Fax: +44 (0)1928 571988

Send Enquiry | Company Information

Connect Opto 22 I/O to Allen-Bradley PLCs

Product News Wednesday, June 11, 2008: System Devices UK Ltd

Built on the standard TCP/IP suite of protocols, EtherNet/IP gets the “IP” part of its name from CIPTM, the Common Industrial ProtocolTM. As the name implies, EtherNet/IP adapts CIP to standard Ethernet technology, and thus provides tools to deploy manufacturing applications on an enterprise network. Introduced in 2001, EtherNet/IP is now supported by hundreds of vendors around the world and is a standard networking solution in industrial automation.

By supporting EtherNet/IP, SNAP PAC controllers and brains can communicate with other manufacturers’ devices that also support EtherNet/IP. This allows you to integrate SNAP PAC devices into automation environments currently populated by equipment from Siemens, Allen-Bradley, WAGO, and others.

Opto 22 Advantage

With EtherNet/IP support in SNAP PACs, you can add the rich and sophisticated functionality of Opto 22 equipment to your EtherNet/IP systems. While other manufacturer’s devices may report only states and counts, our SNAP PAC System devices can report a wealth of functions, including PID loops, high-speed counting and latching, alarming, serial device data, and so on.

Opto 22 Products

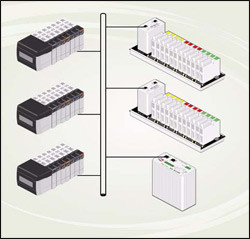

You can use any device from the SNAP PAC family of products in an EtherNet/IP environment, including the latest generation of SNAP PAC controllers and brains. There are two basic approaches:

- Use SNAP PAC S- and R- series controllers to send scratch pad variable data to an EtherNet/IP enabled scanner such as an Allen-Bradley PLC.

- Use SNAP PAC I/O with a SNAP PAC EB-series brain to deliver I/O data to an EtherNet/IP enabled scanner such as an Allen-Bradley PLC.

Adapter

An adapter cannot store or originate the data communications parameters necessary to establish a connection. Therefore, it cannot originate real-time I/O data connections, which is why it sends and receives I/O data only when it is requested to do so by a scanner. Adapter class devices receive message requests from all other classes of products, and they may exchange peer data using messages with any class of device, but they cannot originate such relationships.

Scanner

A scanner is capable of originating I/O data connection requests with adapter class products, as well as with other scanner class products. Scanner class devices may also originate or be the targets of explicit connection requests to and from other classes of products, and they can send or receive messages to or from all other classes of products.

SNAP PAC Implementation

Our SNAP PAC controllers are implemented as adapters, and as such are able to send and receive data only when requested to do so by a scanner. The controller (or adapter) is therefore a target of instructions and requests for information sent by a scanner, which is usually a PLC, or it might be a PC running control software.

Explicit Messaging

Contained in each explicit message is a pre-defined CIP protocol that states the meaning of the message. Explicit messages transport one data item at a time, and they provide the means for typical request/response oriented functions such as module configuration. Explicit messages are typically point-to-point. For explicit messaging between a scanner and SNAP PAC devices, no special configuration is required on a SNAP PAC device, but the scanner must be programmed to send the explicit message request. For example, an Allen-Bradley ControlLogix PLC can be programmed to send an explicit message to our device to invoke service 14 against attribute 137 of instance 1 of class 10 on our SNAP-PAC-R1. This means to read the current input value for point 0 as a REAL (floating point) data type. Using explicit messaging, every class we implement can be accessed in this manner.

Implicit Messaging

Also known as I/O messaging, implicit messages contain no protocol information, only real-time I/O data. That means that the format must have already been defined when the connection is established, so both devices understand it. A target adapter responds to connection requests from a scanner by producing and consuming I/O messages. The advantages of implicit messaging are speed and efficiency. Typically, an implicit message might report states based on a change of state or time. Since the format is already defined, the message is faster to send and interpret. In addition, implicit message connections typically use UDP/IP resources to multicast messages to multiple destinations, so that only one message packet is sent, but many scanners that need the same data receive it simultaneously. Each implicit message contains a single block of data that is referred to as an assembly object or just assembly. The block size is limited to 512 bytes of data.